Marking World Environment Day: MLP UK cuts plastic waste through clever change

Since 1973, the United Nations Environment Programme (UNEP) has celebrated World Environment Day on June 5. The purpose of this day is to raise awareness of efforts to mitigate and remediate the impact of industrial processes, safeguard our ecosystem, and restore our planet. It empowers governments, businesses, communities, and individuals to drive sustainable change.

Each year has a different theme related to environmental issues of global concern. The 2025 campaign is #BeatPlasticPollution and encompasses the global treaty to end plastic pollution.

Today, the world produces around 400 million tonnes of plastic waste each year. Around 36 percent of all plastic produced is used for packaging, including single-use plastic products for food and beverage containers. Of this, 85 percent ends up in landfills or as unregulated waste.

To mark the occasion of World Environment Day 2025, let’s look at an example from MLP UK where they are taking positive steps to reduce plastic pollution.

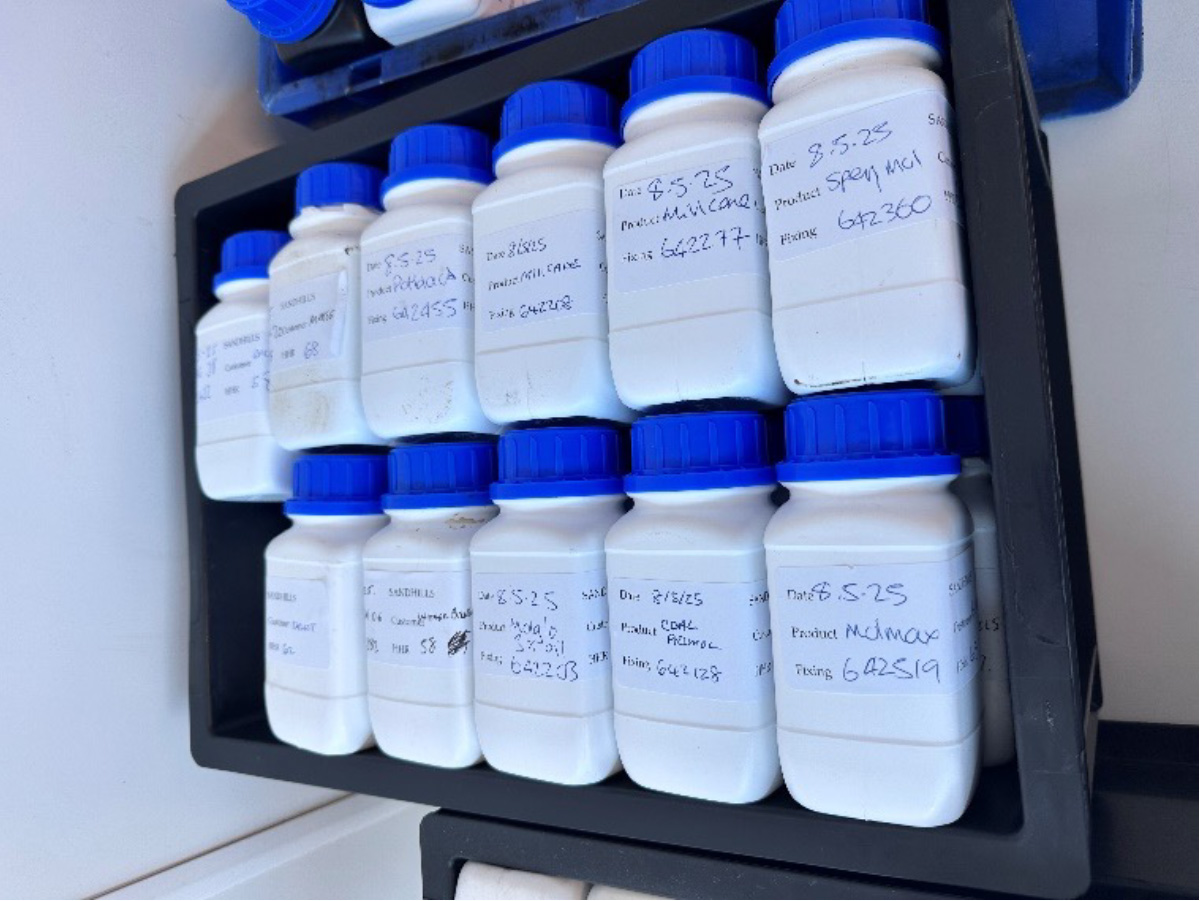

The Sustainability team at MLP UK started looking for ways to minimise waste in 2022. As part of her role, MLP UK Quality Assistant Holly Seddon runs analysis on retain samples from all MLP terminals across the UK and Ireland in compliance with the sampling schedule set out by the Quality Management System. Theses samples are taken and stored in ‘single use’ plastic bottles. One idea originated from an observation made by Holly in a local pub. She noticed how the glasses were being washed and realised that the same method could be used for the plastic molasses retention sample bottles that are a critical part of the company’s processes.

This realisation marked the beginning of the work on the team’s bottle washing machine project. In 2024, the team purchased the machine, which has the capacity to wash more than 650 bottles per week and thus service all UK terminals combined. The molasses from the bottles is now used in non-feed products, and the wastewater from the machine is collected and sent to a biogas plant, where an anaerobic digester uses microorganisms to degrade the organic compounds in the wastewater to produce biogas.

Legislation requires these sample bottles to be retained for six months. Typically, after that period they would have been placed in an open skip and sent to landfill. Holly discovered that in 2024 MLP UK purchased 33,799 non-recyclable plastic bottles with a cost at 83p each, totalling £28,053, while waste skips cost an additional £2,316 each.

As a result of this project, sample bottles are reused up to three times, reducing waste and saving an average of £20,000 per year.

‘A simple observation at a pub led us to an important change in our ways of working,’ says Holly, pictured here. ‘By adding a bottle-washing machine, we are extending the use of our sample bottles and have drastically reduced the number of bottles sent to landfill after a single use – it’s a clear win for the environment and for our operations.’